Traditionally gift cards are made with one or more unique printed codes (called variable data). This unique variable data on the reverse of the card is what gives the card its value.

There are currently two main ways to 'active' the variable data on a gift card. (Whether plastic or plastic alternative gift cards).

POSA (Point of Sale Activated)

The card holds no value (data) until activated at the till point. The till scans the magnetic stripe or barcode which submits a request to the processor. This is to ensure the purchase is legitimate.

At this point, the card is activated ('live') and the value is loaded onto the card.

PIN (Personal Identification Number)

For most online redemptions, the gift card holds a value before purchase. The data is securely held in the PIN. To protect the PIN from being accessed a self-adhesive scratch-off label is placed over the pin. Once purchased the user can scratch off the sticker (label) to access the PIN.

However, there is a long-standing issue in the gift card industry; organised crime and fraud. There is no official number as to the financial impact of gift card fraud. Although it is predicted to be in the hundreds of thousands.

The standard security label comprises three elements: Glue, acetate and latex. (None of which are eco-friendly).

Potential fraudsters purchase gift cards in bulk from either stores or suppliers. They then remove the label to steal the PIN and replace the destroyed label with a new label.

The cards are then returned (without looking visibly tampered) for someone else to purchase and (re) activate the card. In some instances, the fraudsters then use an algorithm to poll the brand's site and intercept the value, all before the gift card recipient has a chance to use the card.

The current security measure available is to place the gift card in an envelope/case (outer secure wallet). However, the wallet must be destroyed to access the card. The additional security layer adds significant time and cost to the production of the gift card (and a huge waste of resources).

Green Gift Card seek out innovation.

We wanted to create an eco-friendly alternative with improved security methods without the costly outer packaging.

We interviewed our founder Graham Lycett on his new innovative environmentally friendly alternative foil scratch-off for plastic-free gift cards. We are currently pending our patenting for our scratch-off foil solution.

Graham, can you tell me a little bit about yourself in connection with the gift card industry?

"We've [Green Gift Card] been involved with the gift card industry since its inception in 2006. With our very first card being launched into Sainsbury's. And ever since then, we have been active in the gift card sector.

Since the beginning, one thing has stuck out to me. The amount of plastic used for what is a limited-use, single-use card. We know that as a society we needed to find an alternative to plastic. Something that is suitable for the limited life of a gift card.

So, I started my journey to find an efficient and cost-effective way of producing gift cards made from plastic alternatives. The only credible alternative I could find to plastic was paperboard, a type of high-quality cardboard.

And Green Gift Card was born. A brand now synonymous with moving the UK Gift Card Industry away from plastic gift cards to entirely sustainable, environmentally friendly paperboard cards."

So green gift card is built on eco innovation what keeps you inspired?

"The job is never done. There's always something we can improve. We've taken plastic out of the market and replaced it with a high-quality paper board. Now an accepted standard industry practice, expected by both consumers and brands.

Our cards are designed to be easy to recycle in existing recycling ecosystems. Even if a card does make its way to a landfill, it is harmless to the environment and will break down. Ultimately composting, subject to the conditions.

What keeps me inspired is there's always room for improvement. There are always other elements in the supply chain that can be made more environmentally friendly.

Whether it's the clear wrapping that the cards go into, the inks involved in printing or the actual manufacturing process. There are always ways to improve and reduce the environmental impact of gift cards. Whether it's their production or what happened to them at the end of life."

What issues does the gift card industry currently face when it comes to security?

“Currently, a lot of gift cards are purchased via a third-party gift card malls in supermarkets. Commonly produced in the PIN format. That pin number is secure and usually covered with a scratch-off label.

Scratch-off labels serve two purposes. Firstly, they conceal the number, or value, of the product. Secondly, they provide a way to check if it has been manipulated. Gift cards that look to have been tampered with cannot be purchased or returned.

Current adhesive labels are made from acetate film and the back is coated with glue and sealed with a carbon-based latex. Unfortunately, these types of labels are can be prone to abuse. Potential fraudsters can lift that label to reveal the pin number underneath.

To add another level of security, companies will often produce secure packs. This additional element creates more cost and increases the product's carbon footprint.

The secure packs do ensure that the card is protected, however, they do not create a particularly good unboxing experience. By absolutely destroying the outer packaging the gratification of the physical object has gone. This is not an ideal solution as there is an impact cost to both the product's carbon footprint and a negative customer experience.”

How can your latest innovation improve the security of gift cards?

“The idea for updating the scratch-off label was a combination of two things. First to find something that was more secure than the current latex scratch-off label. Second, to produce something with a lower carbon footprint and lower environmental impact than its predecessor.

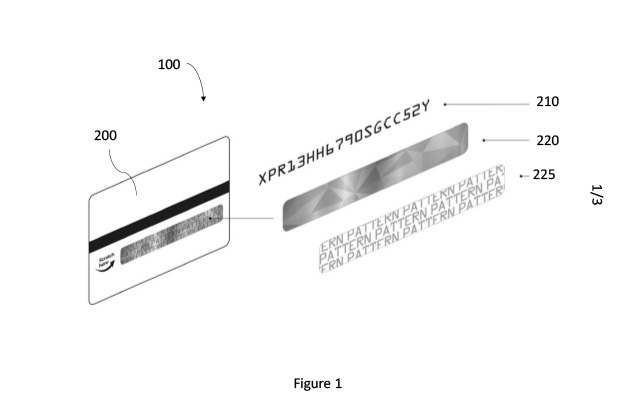

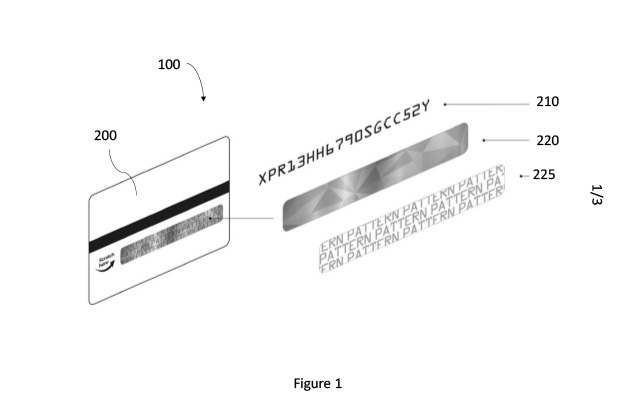

What we've created is a foil-based solution that is applied directly to the substrate. Not via an acetate layer so there's no glue, no acetate, and no carbon layer on top.

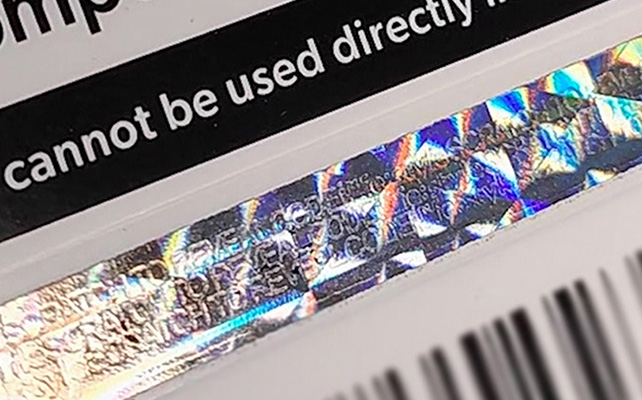

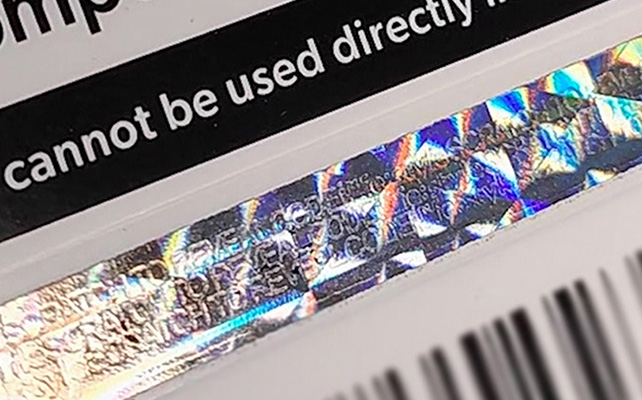

The main material used in our foil solution is Aluminium. This natural mineral is incredibly thin. What we've developed is a holographic foil which makes a secure, three-dimensional embossed textured overlay directly on the card.

The 3D embossing adds an extra security feature that is very difficult to replicate. Not only is our product less damaging to the environment, because it is made from a natural mineral, aluminium, the aluminium is much more secure than a scratch-off label.

Our foil is completely tamper-proof. Unlike traditional scratch-off labels, ours are applied directly to the card. It cannot be peeled off or replaced once scratched off. This is because of the residual marking left behind which is very difficult to clean up and hide.”

What are the environmental benefits of the new foil scratch-off?

“Our foil scratch-off is made of a four-micron thick layer of aluminium and some additives that give it an elasticity which allows it to be scratched off. The foil has a black layer at the back, creating an absolute blackout. This prevents the PIN number from being revealed, even by shining an intense light through the reverse of the card.

Our foil scratch-off alternative does not affect the eco integrability of our paperboard eco gift cards. The paperboard will naturally bio-degrade, leaving only the foil. Which is a natural mineral on non-toxic to our environment.

Our Aluminium is free from contaminants and is significantly less harmful to the environment than the existing plastic acetate layer, comprised of glue with a carbon base latex layer on top.”

Finally, what are you looking forward to in the gift card industry?

“As gift card manufacturers, the next big change that I would like to see is the reduction of high-volume card production, citing short run digital print as the credible alternative.

This would reduce the mountains of gift cards made every year. Of which a large proportion waits in warehouses going unused and going out of date. Gift cards can become obsolete due to changes in a brand's terms and conditions or even a logo change.

These changes can include anything that impacts the brand. Multi-brand cards are subject to this even more if a contributing brand goes out of business for example. To become more sustainable, we need to move away from a model of buying high volumes. The idea behind high volume is to drive the price down.

However, with high storage and transport costs, in both Pounds and Carbon storing the gift cards can become costly. We suggest a more agile model where you print what you've sold, and nothing more. This ensures a lean supply chain and a lower carbon footprint. For me, that's kind of the next significant change.

I would like to see the UK transition from using magnetic stripes to barcodes for activation and redemption. This would be beneficial for many reasons. Barcodes and QR codes more secure and can store more information than magnetic stripes. They are also more easily scanned, saving time and energy.

Magnetic stripes contain iron and a polyester release film. This film must be treated before disposal. It can only be incinerated or buried at a landfill. Again, not a sustainable option.”

How can your latest innovation improve the security of gift cards?

“The idea for updating the scratch-off label was a combination of two things. First to find something that was more secure than the current latex scratch-off label. Second, to produce something with a lower carbon footprint and lower environmental impact than its predecessor.

What we've created is a foil-based solution that is applied directly to the substrate. Not via an acetate layer so there's no glue, no acetate, and no carbon layer on top.

The main material used in our foil solution is Aluminium. This natural mineral is incredibly thin. What we've developed is a holographic foil which makes a secure, three-dimensional embossed textured overlay directly on the card.

The 3D embossing adds an extra security feature that is very difficult to replicate. Not only is our product less damaging to the environment, because it is made from a natural mineral, aluminium, the aluminium is much more secure than a scratch-off label.

Our foil is completely tamper-proof. Unlike traditional scratch-off labels, ours are applied directly to the card. It cannot be peeled off or replaced once scratched off. This is because of the residual marking left behind which is very difficult to clean up and hide.”

What are the environmental benefits of the new foil scratch-off?

“Our foil scratch-off is made of a four-micron thick layer of aluminium and some additives that give it an elasticity which allows it to be scratched off. The foil has a black layer at the back, creating an absolute blackout. This prevents the PIN number from being revealed, even by shining an intense light through the reverse of the card.

Our foil scratch-off alternative does not affect the eco integrability of our paperboard eco gift cards. The paperboard will naturally bio-degrade, leaving only the foil. Which is a natural mineral on non-toxic to our environment.

Our Aluminium is free from contaminants and is significantly less harmful to the environment than the existing plastic acetate layer, comprised of glue with a carbon base latex layer on top.”

Finally, what are you looking forward to in the gift card industry?

“As gift card manufacturers, the next big change that I would like to see is the reduction of high-volume card production, citing short run digital print as the credible alternative.

This would reduce the mountains of gift cards made every year. Of which a large proportion waits in warehouses going unused and going out of date. Gift cards can become obsolete due to changes in a brand's terms and conditions or even a logo change.

These changes can include anything that impacts the brand. Multi-brand cards are subject to this even more if a contributing brand goes out of business for example. To become more sustainable, we need to move away from a model of buying high volumes. The idea behind high volume is to drive the price down.

However, with high storage and transport costs, in both Pounds and Carbon storing the gift cards can become costly. We suggest a more agile model where you print what you've sold, and nothing more. This ensures a lean supply chain and a lower carbon footprint. For me, that's kind of the next significant change.

I would like to see the UK transition from using magnetic stripes to barcodes for activation and redemption. This would be beneficial for many reasons. Barcodes and QR codes more secure and can store more information than magnetic stripes. They are also more easily scanned, saving time and energy.

Magnetic stripes contain iron and a polyester release film. This film must be treated before disposal. It can only be incinerated or buried at a landfill. Again, not a sustainable option.”